Organic Cold Pressed Peanut Oil

Pure Nutrition by Organic Cold Pressing

Raw materials are produced in the first workshop of its own organic planting base, organic planting throughout the process, to eliminate chemical fertilizers, pesticides and other pollution.

In the process of production, we strictly follow the standards of organic food production, collection, processing, packaging, storage and transportation, and do not use any additives and GM technology. The whole process can be traced organically.

Organic fertilizer, pesticide-free.

The national invention patent for low-temperature preparation technology has improved the retention rate of nutrient components of peanut oil, natural peanut fragrance and low oil fume.

Organic is a kind of life attitude, pursuing healthy life attitude, organic makes life better.

-

450ml

-

1.6L Iron Box

-

3L Iron Box

-

900ml

-

900mlx2 (light pack)

-

900mlx2

Specifications | 450ml | 900ml | 1.6L | 3L | 900ml*2 | 900ml*2 |

| PET Bottle | Iron Bucket | Gift Box | Gift Box(Plain clothes) | |||

Pathfinder

Pioneer of Cold Pressing Oil Technology

Grasp the Core Technology and Lead the Future of the Industry

Changshou Food regards "providing high-quality peanut oil for consumers" as its responsibility, introduces advanced equipment from abroad, and finally successfully develops "the method of low-temperature preparation of original peanut oil and textured protein". It completely overthrows the traditional hot pressing and leaching technology of peanut oil industry, and leads the edible oil into a new era of cold pressing.

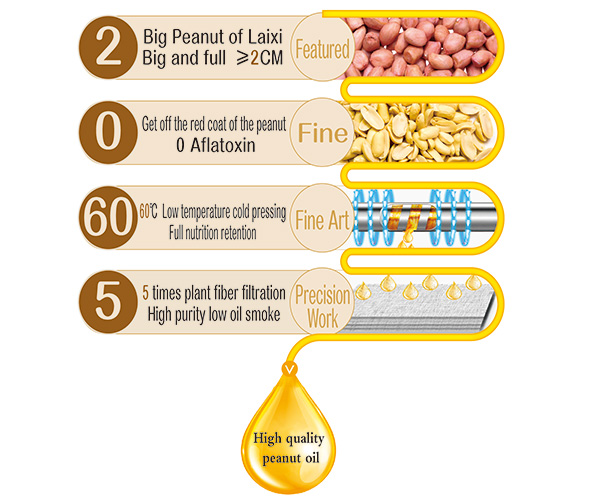

Processing Technology of Peanut Oil

-

Before the 1990S

Peanut oil is mostly bulk oil, which is difficult to ensure hygiene and quality, and its production technology is on the verge of elimination.

-

Early 21st Century

Small package oil gradually replaced bulk oil, and high temperature pressing (120 C or more) technology became the most adopted technology in peanut oil industry and brand.。

-

Nowadays

The first cold-pressed peanut oil adopts the national invention patent "low temperature cold-pressed" technology, which opens a new era of peanut oil cold-pressed.

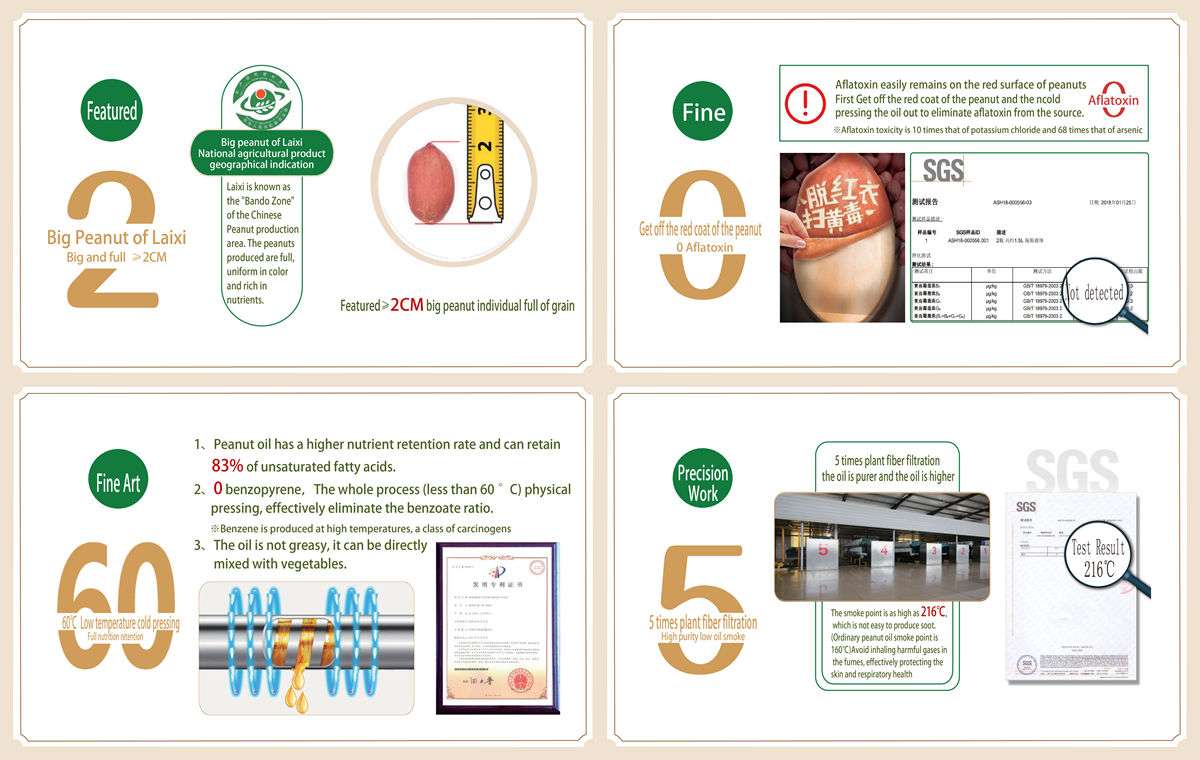

Process Analysis

| Cold pressing and hot pressing of PK | ||

| Indicators | First Fang Cold Pressed Peanut Oil | Traditional Peanut Oil |

| Pressing Technology | Cold pressing (below 60 degrees C) | Hot pressing (120 degree C) |

| Raw Material | Export grade peanut (full grain) | General grade peanut |

| Removal of Red Clothes | There are (sources eliminate aflatoxins) | Nothing |

| Classification and screening of raw materials | Level 5 (higher level) | Level 1-2 (lower level) |

| Nutritional Components | Retaining Peanut Nutrition (83% Unsaturated Fatty Acids) | Partially destroyed |

| Fume concentration | Very low (high smoke point, no pollution) | Higher |

| Multilayer Plant Fiber Filtration | Yes (five floors) | Part |

| Aroma type | Natural peanut fragrance, but not greasy salad | Ripe fragrance |

Product Advantage

Three Product Advantages Benefiting Consumers

-

High nutrition

Nutritional ingredients are retained more fully

60°C Low-temperature pressing, higher retention rate of nutrients (monounsaturated fatty acids, polyunsaturated fatty acids, vitamins, minerals); select large peanuts of export grade, full granules, nutrient-rich, eliminate aflatoxin, health and safety is guaranteed.

-

To purity

Two Physical Refining and Multilayer Plant Fiber Filtration

Low temperature physical de-red coat, 2 times physical refining, multi-layer plant fiber filtration, natural peanut fragrance.

-

Low Soot

Low temperature treatment, not easy to produce lampblack

The whole process of low temperature treatment, peanut cell structure remains intact, less impurities, not easy to produce lampblack.

Six considerate designs

-

Easy-To-Pull Cap

The arc design is not easy to break, easy to open and save time and effort.

-

Reflux Bottle Mouth

Funnel-shaped subsidence design to prevent remaining oil from retaining bottle mouth

-

Controllable Oil Outlet

Flow diversion design, pouring oil without gushing, easy control of oil volume

-

Accurate Calibration

Clear, accurate and scientific control of daily oil consumption

-

Bottle shoulder handle 1.8L

Cooperate with kitchen basket, not easy to slip when lifting

-

Widening handle 4.5L

Widening design holds comfortable hands

Planting BaseBase

Basic Requirements for Planting Organic Food Raw Materials

The cultivation process does not use pesticides, insecticides, synthetic (chemical) fertilizers, but uses natural fertilizers (composts) to feed the soil, which has added soil nutrients, and the production units need to establish long-term land fertilization, plant protection, crop rotation plans.

No Soil and Water Loss and Other Environmental Problems in Production Bases

Pesticides, synthetic (chemical) fertilizers, pesticides, chemical additives shall not be used in production, harvest and processing.

The conversion of soil from conventional planting to organic planting requires three years of fallow cultivation.

The whole process of production must have complete records.

The first cold-pressed peanut oil organic planting base only cultivates peanut crops, and no other crops are planted for half a year outside the peanut cultivation period, so as to restore the soil.

Organic certificationAttest

Organic food is the highest food safety standard

Basic Requirements of Organic Food Processing

Raw materials must be certified organic products.

Only organic condiments, pigments and spices are used as auxiliary materials, and no synthetic additives are used.

Organic food avoids chemical contamination in the process of production, processing and transportation.

Certificate of Organic Certification

Certificate of Organic Certification

Consumer Experience Case

Young urban white-collar Xiaoxin

At first sight, it was attracted by its charming appearance, which was unprecedented transparency and purity. Bright, let people feel good from the beginning.

At first sight, it was attracted by its charming appearance, which was unprecedented transparency and purity. Bright, let people feel good from the beginning.

Its taste is refreshing and refreshing.

It is a good companion for a healthy life - the first workshop of peanut oil.

Career executives, supermothers and all-around housewives

Enjoy delicious food with your family on weekends.

Sweet and sour jellyfish, vegetable salad, fried yellow croaker, fried rape and fried lotus root are all in color, aroma and taste.

The child cried happily, "It's delicious". The lover also laughed and said:

"This dish tastes different from what you did before. It's very fragrant."

I laughed happily, but they didn't know that I had a secret weapon, the first workshop of peanut oil.

Pure and transparent appearance, but its charming exterior.

High nutrition and low lampblack are the most attractive places for me.

It can be salad, fried, cooking oil, that is to say, nutrition and health.

200 g jellyfish is washed and soaked for 4 hours. Cucumbers are shredded and garlic puree is prepared. The jellyfish is boiled in boiling water, washed and cooled, then put in a bowl. Put the cucumber shredded and garlic puree into a bowl filled with jellyfish silk. Add sugar, sauce and fragrant oil in turn. Finally add vinegar and cold pressed peanut oil in the first place. Mix well and serve.

Corn kernels can be cooked in a pot with a spoonful of salt and a little of the first pot of peanut oil. Diced tomatoes, boiled eggs and diced eggs. Put all the ingredients cut into small dices in a big bowl. Add the first dish of peanut oil, salt and black pepper and mix well.